Excel spreadsheet is an excellent software to help Quantity Surveyor to do taking off and expedite the process of preparing a Bill of Quantities. The main thing to consider in preparing a taking off template is to know basic Excel commands, and to be able to use formula and links. The followings are general rule to follow when preparing a template.

1. Create one sheet for the taking off list. It is better to arrange the list in accordance with the final Bill arrangement, so that Bill preparation can be done easily. After preparing the list, sort the list in accordance with the final BQ arrangement.

2. Create sheet2 as the taking off portion.

3. Link the descriptions in sheet 1 to sheet 2, by using "=" sign.

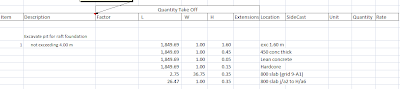

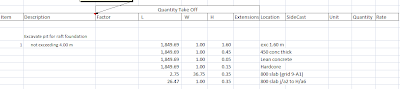

4. The template for taking off should look something similar to the following:

5. Provide a complete description of the item.

6. Follow the sequence of L, W, H in taking off. For Linear item, only L will have the measured quantity, but for W and H insert the value = 1. For Unit of M2, then L and W or H should have the quantity, and W or H for the next dimension = 1.

7. Factor column is similar to timesing, indicating the number of occurrence of the item.

8. For item that need to be deducted, insert the factor column as -1, or if the quantity to be deducted is more than 1, insert the actual deduction quantity.

9. As there will be more measurement for an item, use command insert to insert the row.

10. For any measurement carried out, state the location by making reference to the grid, or room location or any other indication that can be read from the drawings.

11. Extension column can be left blank, but will be used later when we need to perform quantity squaring.

12. It is important to link the measurement where relevant, and applicable. Linking will ensure that a single dimension, also applicable to other dimension. So that in the event there are changes to the quantity, a single change may affect other dimension too. However, this rule may not necessarily help in cases when the linked quantity is rigid. In cases when a single change does not affect other quantity, individual items must be tracked to check for changes.